How much easier would our lives be if, like our bodies, our possessions could regenerate their own material to fix any damages they sustained?

Well, thanks to some very clever folks in England, concrete could be made self-regenerating by the addition of a simple enzyme found in our blood—repairing cracks in the sidewalk, roads, or buildings—saving tons of CO2, as well as millions in dollars, labor hours, and traffic slowdowns.

Recent estimates put the global concrete supply chain at 8% of the world’s greenhouse gas emissions, more than three-times that generated from the airline industry. One of the most prevalent human materials also requires the largest supporting infrastructure, from mining, to mixing, to moving, to laying and repairing, it’s a massive effort.

Worcester Polytechnic Institute led a project into looking at concrete that repairs itself, which has been hypothesized as possible since the mid-’90s, and which was recently confirmed as possible with bacteria in 2015.

MORE: The House That Hemp Built: Moldproof, Fireproof and Eco-Friendly

Like earlier researchers, the team at Worcester, led by Nima Rahbar, used an enzyme found in red blood cells called “carbonic anhydrase,” at the suggestion of a biochemist collaborator of theirs.

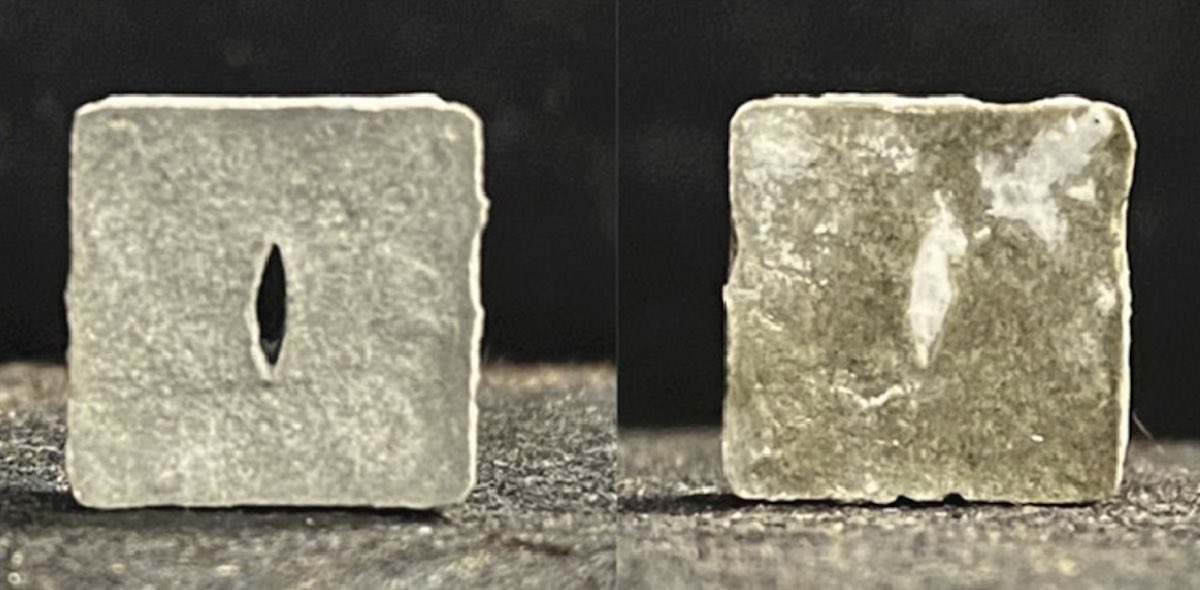

The anhydrase is responsible for moving CO2 from our cells to our blood vessels as quick as our breathing, and when added to concrete powder, it actually uses CO2 from the air to create calcium carbonate crystals. A millimeter crack can be filled in after just several hours, preventing larger cracks from forming. Anhydrase was among the reasons the bacteria was able to repair concrete.

Another method is adding carbonic anhydrase to water and calcium together in a spray and applying it to a concrete crack. If CO2 is then blown over the crack, like Wolverine from X-Men it will seal itself in just minutes, while if it simply uses the CO2 in the air it will take longer.

Astute readers will recognize that this technology also sucks some CO2 out of the environment, which along with extending the lifespan of the concrete four-fold, allows it to become a carbon jailer as well.

RELATED: Ancient Roman Concrete Reveals Secret to Cutting Carbon Emissions

A peer-reviewed study demonstrated the technology’s effectiveness, which Rahbar hopes will lead a startup somewhere to develop a commercial version to bring to market.

“This is not going to cost much,” Rahbar told Fast Company. “But overall, the system requires some incentive.”

BUILD Positivity in Your Friends’ Lives—Share the Results of This Research…

Good news! Now Al Gore can invest his $300 million to get that carbon concrete technology into production. Right, big Al?