Centuries ago, alchemists thought they could turn lead into gold. Today, the prospect of coaxing valuable materials from abundant resources guides scientists who have seen a golden opportunity.

The U.S. Department of Energy’s Pacific Northwest National Laboratory is working with companies to test an approach that uses magnetic nanoparticles to capture critical materials, such as lithium, from various wastewater sources.

Lithium is an essential ingredient in many electronic and energy technologies, including the lightweight lithium-ion batteries that power everything from our phones to electric vehicles.

The global market for lithium is huge, but precious little is produced in the United States.

Not only does the patent-pending technology being developed at the Lab in Richland, Washington, provide an opportunity to produce lithium and other critical materials, it does the job much faster and at a lower cost.

At the heart of the process are magnetic nanoparticles surrounded by an adsorbent shell that latches onto the lithium and other metals found in water that is used in various industrial processes. That includes the water in geothermal power plants, known as geothermal brines, or water pulled from the subsurface during oil or gas production.

Lithium is present in much of water pumped during oil and gas extraction across the U.S. and Canada. PNNL scientists estimate that if just 25 percent of the lithium in such water were collected today, it would equal the current annual worldwide production. Testing is ongoing, involving PNNL, Moselle Technologies, Canada Natural Resources Limited, and Conoco Phillips. The team is stress-testing the technology by “subjecting it to extended cycle testing with the magnetic separator system, a needed step for full-scale industrial production,” reports PNNL.

RELATED: Scientists at Stanford Revitalize Batteries By Bringing ‘Dead’ Lithium Back to Life

“By using the magnetic nanoparticles to attach to the lithium particles in solution, we expect the resulting concentrate to be in a purer form, thereby reducing the cost of further processing, and this will take out more than half the cost,” said CEO Jerry Mills of Moselle, the Texas company which has licensed the tech and plans to pilot it in several locations.

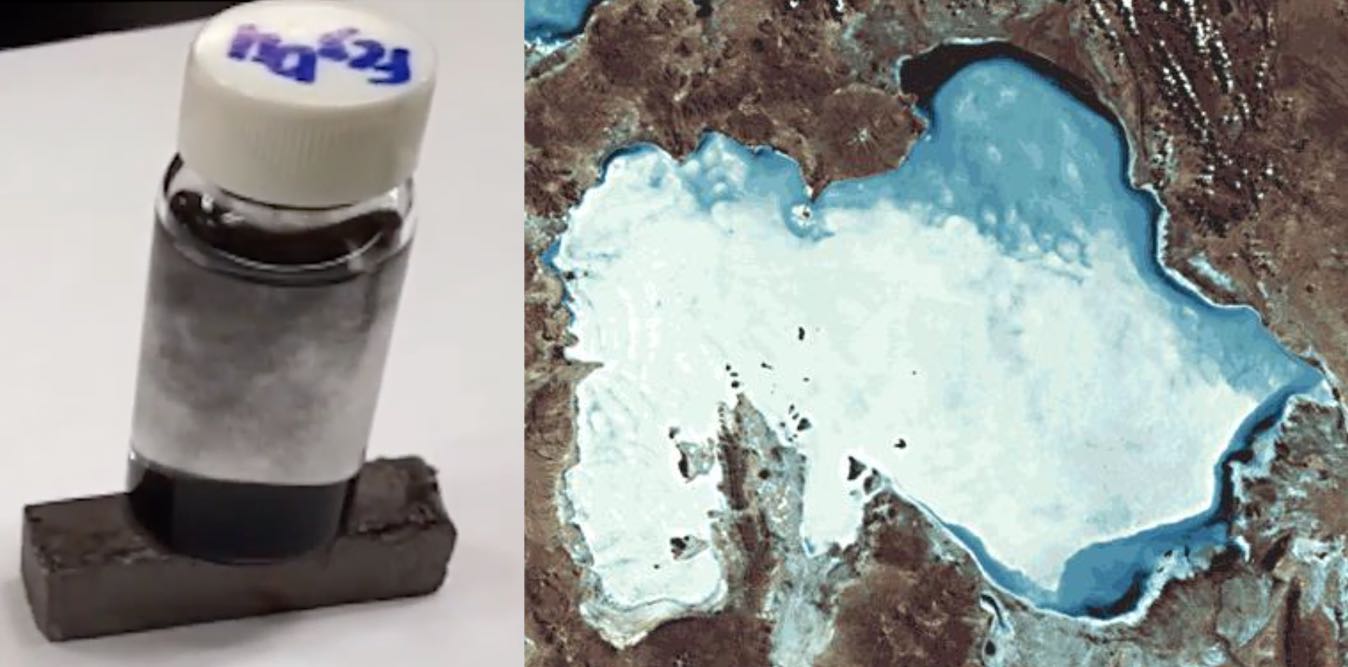

Once the tiny, iron-based particles are added to the water, the lithium is drawn out of the water and binds to them. Then, with the help of a magnet, the nanoparticles can be collected in just minutes with the lithium hitching a ride, no longer suspended in the liquid and ready for easy extraction. (See an example in the video below—with no audio.)

Best of all, after the lithium is extracted, the recharged nanoparticles can be used again. The process also could be used in effluents from desalination plants, or even directly from seawater.

RELATED: New Technology is Recycling Tons of Lithium-Ion Batteries in Canada and the U.S.

The PNNL process goes to work immediately. Compare that with conventional lithium extraction methods that pump groundwater into large, costly evaporating ponds—which take months or even years to evaporate enough to access the lithium, and impact groundwater management in arid regions where they are mainly deployed (mostly Australia, Chile, and China).

Geothermal boost and beyond

If this technology were deployed at geothermal plants, the value of recovered lithium could potentially increase the cost-effectiveness of this form of clean renewable energy, which uses water to capture the heat deep below the Earth’s surface and then converts it into green electricity.

In addition to Moselle, they are teaming with other commercial partners to evaluate the use of the technology for their lithium resources in Nevada and Canada.

Finally, with an eye on a different set of applications, researchers at PNNL are customizing the shell of the nanoparticle to specifically target other commercially valuable elements and minerals used in energy technologies, medical imaging devices, and more.

MORE: Long-lasting Solid-state Lithium Battery From Harvard May Solve a 40-year Problem

For example, they are collaborating with Moselle and Geo40 to explore the possibility of extracting cesium and antimony from geothermal brines at a geothermal plant in New Zealand.

“PNNL’s novel approach is truly remarkable,” says Steven Ashby, director of Pacific Northwest National Laboratory. “It offers the promise of extracting critical minerals in a quick, cost-effective manner. And innovation like this just might be worth its weight in gold.”

THIS News is Proof of Progress for the Planet…SHARE it on Social Media…