Kirigami, the ancient Japanese art of cutting paper, has been adapted by researchers at Virginia Tech to make sticky tape much stronger, yet easier to remove than current super-adhesives.

From quickly fixing household items to ensuring a reliable seal on a package to be mailed, it’s helpful to have tape with a strong bond—but removing it may only be possible by scraping—and hoping surface pieces don’t tear away.

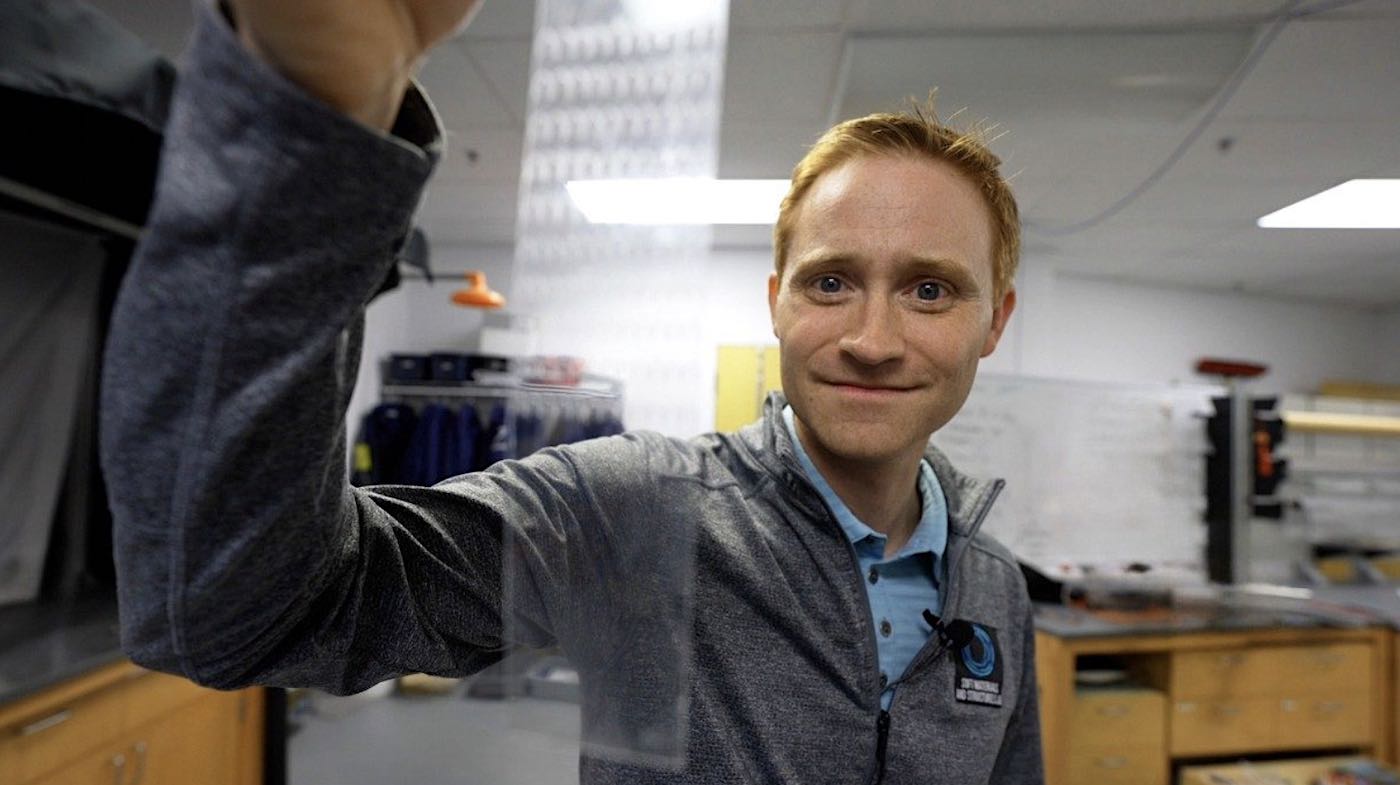

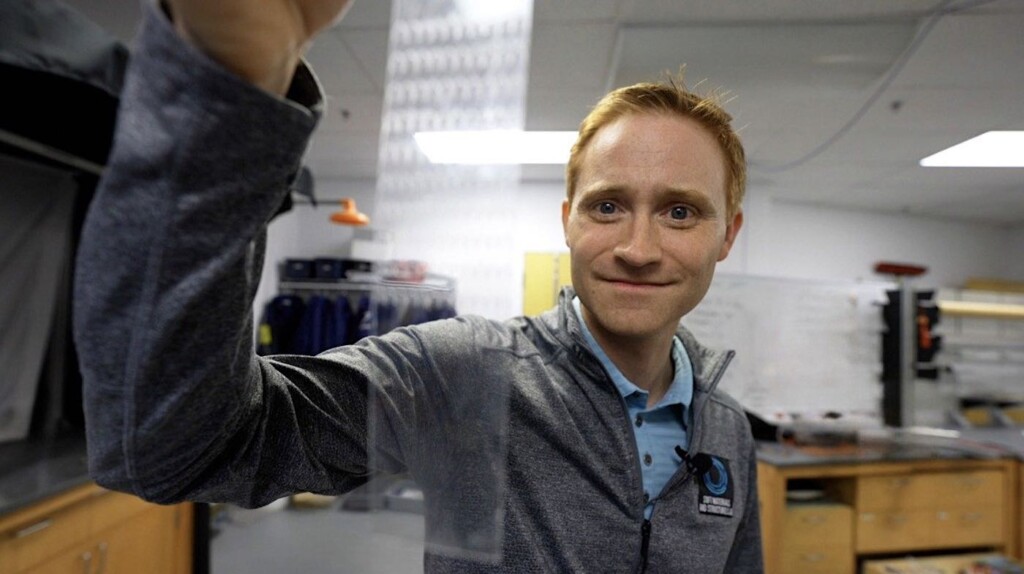

Professor Michael Bartlett’s university team succeeded in massively increasing the adhesive bond but also make the substance easily removable.

“This seemingly paradoxical combination of properties could dramatically change applications in robotic grasping, wearables for health monitoring, and manufacturing for assembly and recycling,” explained Prof. Bartlett.

Easily removable masking tape was first developed in the 1920s to meet a need for car painters who wanted better options for painting two colors on vehicles. Since then, factories have rolled out invisible tape for wrapping presents, electrical tape for covering wires, and duct tape for more uses than it was ever intended to fill.

“Normally, when tapes are peeled off, they separate in a straight line along the length of the strip until the tape is completely removed. Strong adhesives are made more difficult to peel, while reusable adhesives promote the strength-limiting separation.”

Bartlett’s tried to control the “separation path”, inspired by kirigami which uses folding and cutting to transform a flat sheet of paper, the method kids use when creating paper snowflakes.

LOOK: Forget Harry Potter’s Cloak, a Real-Life Invisibility Shield is Now Taking Orders

They made a series of U-shaped cuts across an adhesive, and found that applying these cuts made the bond of the tape stronger by a factor of 60.

“An engineered cut can force the adhesive separation path to go backwards at specific locations, which we call reverse crack propagation, making the adhesive very strong. But by peeling in the opposite direction, it always goes forward, making it easy to remove.”

“This is quite unusual behavior, but it is very useful to make strong yet releasable adhesives.”

The team also reported—with published research in Nature Materials—that the type of tape didn’t matter. Kirigami increased the bonds of every type of tape tested, from packaging tapes to medical tapes. In all cases, strong adhesive bonds become even stronger and normally weaker adhesives increased in strength, too.

“What really matters is the shape and size of the cut,” said former graduate researcher Dohgyu Hwang. “We do not have to rely on the specific adhesive material, but as long as the cuts are made at a characteristic size, which is defined by the physics of the adhesive, we found that this enhanced adhesion in every system we tried.”

DISCOVERY: This Iridescent Coating Could Cool Your House Without Air-Conditioning

“We also use a rapid digital fabrication approach, so we can quickly create highly customizable adhesives with tunable strength,” said Bartlett. “This is very exciting for the development of future adhesives.”

Check out the video from Virginia Tech…

MAKE This a Sticky Post on Social Media by Sharing the Breakthrough…