The frigid waters of a bay in northeastern China are the site of a remarkable feat of engineering that’s won global recognition for its accomplishments.

Bolted to the seafloor in six individual segments, the Dalian Bay Undersea Tunnel spans over 2 miles of water and connects the peninsula-bound city of the same name with the mainland.

It was announced as Best Project of the Year by the decades-old American Engineering review, ENR, for its mixture of first-of-its-kind technologies and methodologies used in the construction.

Allowing motorists to avoid the lengthy C-shaped stretch of road around the bay, the trip has been shrunk from one hour to just 5 minutes.

“The team conducted an investigation on offshore concrete structures ranging from 15 to 86 years naturally exposed in the cold sea areas of China,” Sun Zhu, deputy chief engineer with CCCC First Harbor Engineering Co., the lead contractor on the project, told ENR. “Based on this research, a theoretical model was established to predict the 100-year service life of concrete structures in the marine environment of Dalian’s cold region.”

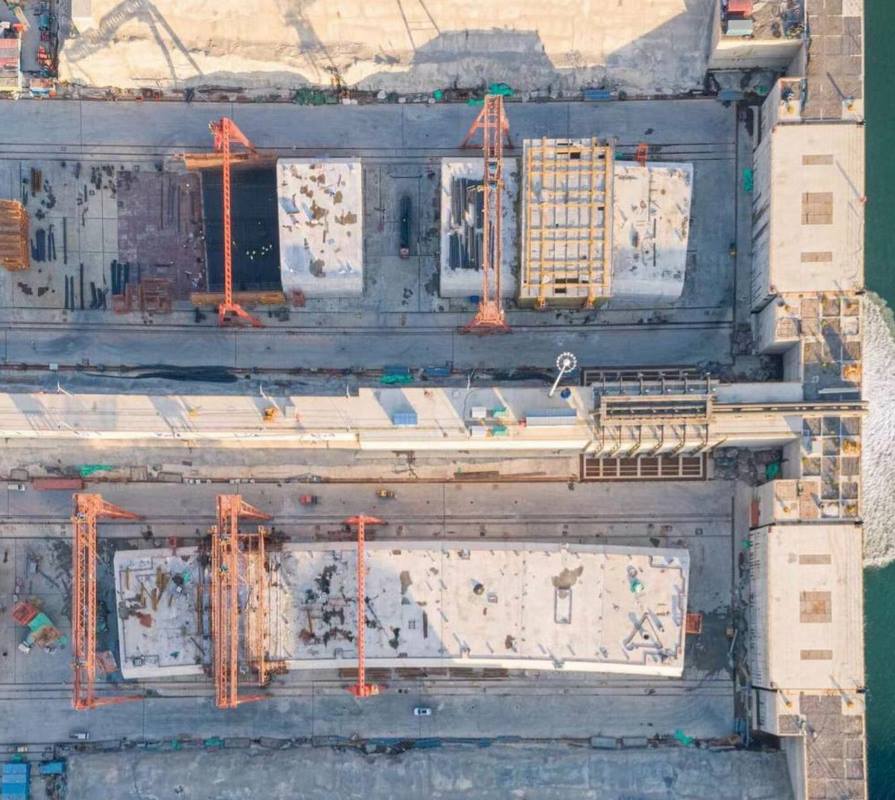

18 tubes of continuously poured concrete make up the undersea structure, each consisting of 7 segments containing 6 lanes for traffic. The tubes, some of which curve to form the tunnel’s path, were assembled 6 at a time along the edge of the bay in the highest capacity dry dock in all of Asia, which was built just for the project.

The total length of the curve adds up to around 1,050 meters, or around 3,200 feet; making it the tightest curve in an undersea tunnel in China. The segments were bolted onto rocks 32 meters below the sea.

Because no such tunnel had ever been built in such cold temperatures, an on-site laboratory was established by First Harbor and its partners that ended up conducting 20 large-scale engineering and physics experiments.

MORE INCREDIBLE ENGINEERING: Sicily Will be Reachable Via World’s Longest Suspension Bridge That Italians Have Wanted for Centuries

Before each of the 60,000-ton tubes was sunk into their positions, they were pre-stressed with cables that would eventually be cut, rendering the tubes of concrete flexible.

“The technological research and development, as well as the preparatory work undertaken in the early stages, played a pivotal role” in the project, Zhu says. “It underscores the importance of advanced planning and prioritizing technology in engineering projects, particularly for large-scale undertakings.”

ALSO CHECK OUT: Awesome Bridge Swings Back and Forth to Allow Boats to Pass Over Long-Divided Scottish River (LOOK)

All 18 tubes were laid in just 20 months, and after assembly wrapped up in April 2023, the tunnel was opened in 2024.

SHARE This Incredible Accomplishment With Your Friends On Facebook…

I wish they had included some pictures!