A team from MIT has discovered a fascinating chemical reaction that could allow ships or submarines to power themselves with zero-emissions hydrogen via a combination of aluminum pellets and the seawater through which they sail.

Several clever tweaks allowed for this process to generate a not-insubstantial amount of hydrogen gas—the kind being used as an alternative to fossil fuels in heavy machinery like construction equipment, trains, and planes.

The tweak was, if one can believe it, a dash of coffee grounds, making the whole process tantalizingly sustainable as the aluminum came from old soda cans.

Hydrogen is being tested in all kinds of applications, and is extremely exciting as a potential replacement for diesel because it has completely zero carbon emissions—the only output is hydrogen dioxide—also known as water.

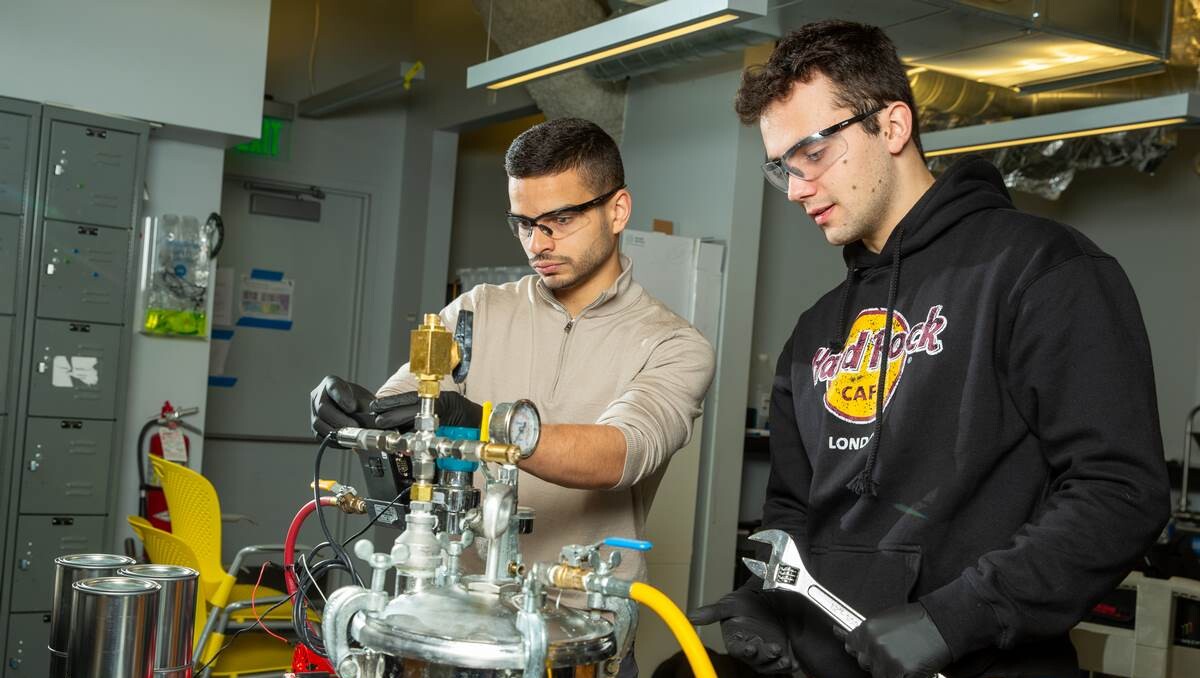

However, hang-ups exist as to the safety of carrying large tanks of hydrogen gas aboard vehicles due to its volatile nature. Aly Kombargi, a Ph.D. student in MIT’s Department of Mechanical Engineering, and his colleagues on the project envisioned using seawater as the hydrogen source, and aluminum pellets as the on-board fuel, a little like how coal was shoveled into steamships once upon a time.

“This is very interesting for maritime applications like boats or underwater vehicles because you wouldn’t have to carry around seawater—it’s readily available,” says Kombargi, lead author on the paper published with the experiment’s results.

The reaction works like this: pure aluminum, when dropped into water, causes a straightforward reaction that generates hydrogen gas. To reduce costs, aluminum soda cans can be used, but only if pretreated with a rare and expensive alloy called gallium indium because the non-pure aluminum in soda cans develops a protective oxide barrier upon exposure to oxygen in the air that prevents the reaction from taking place.

MORE HYDROGEN TECH ADVANCEMENTS: World’s First Electric Aircraft Flight Powered by New Liquid Hydrogen–Flew for 3 Hours

To reduce costs, it would be ideal if the alloy could be recovered—which it can if protected by a barrier of ions. Fortunately, seawater is a highly ionic solution, which allowed Kombargi to scoop out the gallium indium post-reaction.

But the process is long, taking about 2 hours to fully finish. The team started tossing ingredients from their kitchen in to see what if anything might speed the process up. To their delight and surprise, coffee, specifically imidazole, an active ingredient in caffeine, reduced the time from 2 hours down to 5 minutes.

MORE ZERO EMISSIONS ENGINEERING: Pioneering Zero-Emissions Hydrogen Fuel-Cell-Powered Ship Successfully Tested in Japan

Using these ingredients, the team estimates that just 1 gram of pre-treated aluminum pellets would generate 1.3 liters of hydrogen in just 5 minutes.

MIT press reports that the researchers plan to test it first in marine and underwater vehicles. They’ve calculated that such a reactor, holding about 40 pounds of aluminum pellets, could power a small underwater glider for about 30 days by pumping in surrounding seawater and generating hydrogen to power a motor.

SHARE This Amazing Discovery In Sustainable Chemical Engineering…