A radical new fabric that enables temperature-controlled clothing was inspired by squid—and allows for user-adjusted warmth, according to scientists.

Current athletic clothing brands boast temperature-controlling fabrics that may adapt to every climate, with lightweight but warm products. However, American researchers wanted to create a fabric that the wearer can adjust to the specific temperature they need.

Inspired by the color-changing properties of squid skin, researchers from the University of California in Irvine developed a method to manufacture a heat-adjusting material that is breathable—and washable—and can be integrated into the flexible fabric.

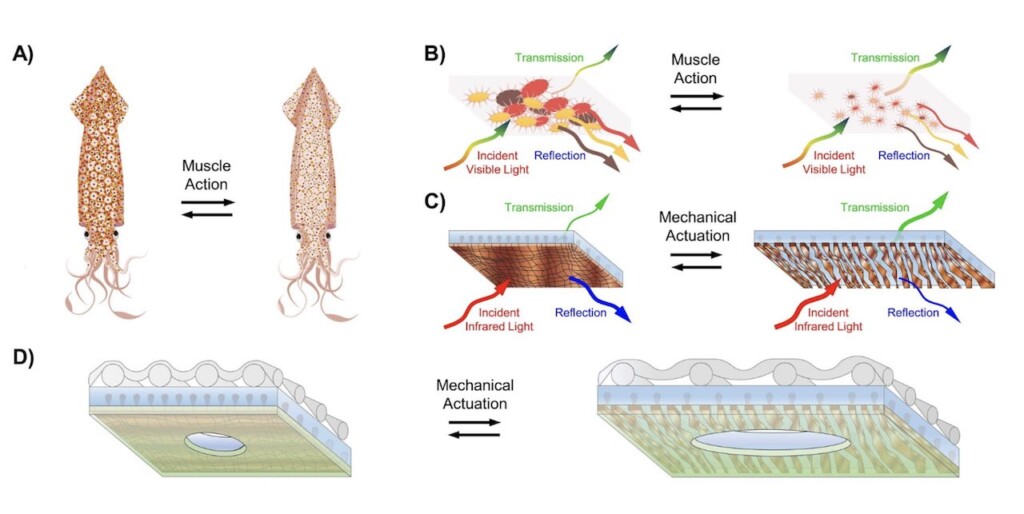

“Squid skin is complex, consisting of multiple layers that work together to manipulate light and change the animal’s overall coloration and patterning,” explained Professor Alon Gorodetsky.

“Some of the layers contain organs called chromatophores, which transition between expanded and contracted states, upon muscle action, to change how the skin transmits and reflects visible light.”

Instead of manipulating visible light, the team engineered a revolutionary composite material that operates in the infrared spectrum, because when people heat up they emit some of their heat as invisible, infrared radiation.

Clothing that manipulates and adapts to this emission and is fitted with thermoregulatory features can finely adjust to the desired temperature of the wearer.

According to the research published in the journal APL Bioengineering, the material consists of a polymer covered with copper islands, and stretching it separates the islands and changes how it transmits and reflects infrared light.

Gorodetsky, who authored the paper, says the innovation creates the possibility of controlling the temperature of a garment.

In previous research, also published in APL Bioengineering, the team modeled their composite material’s adaptive infrared properties. Now they have built on the material to increase its functionality by making it washable, breathable, and integrated into fabric.

The researchers layered a thin film onto the composite to enable easy washing without degradation, a practical consideration for any fabric.

MORE INNOVATION:

• A Polyester-Dissolving Process Could Make Modern Clothing Recyclable

• Color-Changing Inks Can Be Printed on Clothing to Warn the Wearer About Potential Health Issues

To make the composite material breathable, the team perforated it, producing an array of holes. The resulting product exhibited air and water vapor permeability similar to cotton fabrics. The researchers then adhered the material to a mesh to demonstrate straightforward fabric integration.

They tested the material’s adaptive infrared properties and used a sweating guarded hot plate (SGHP) installed in a custom chamber to test the dynamic thermoregulatory properties.

Even with simultaneous thin-film layering, perforations, and fabric integration, the materials’ heat-managing performance did not suffer.

“Our advanced composite material now opens opportunities for most wearable applications but may be particularly suited for cold weather clothing like ski jackets, thermal socks, insulated gloves, and winter hats,” said Gorodetsky.

LOVE THIS LOOK: Fashion Student Makes ‘Memory Bears’ for Grieving Folks From the Clothing Of Their Deceased Loved Ones

He says that as well as the possible applications for the fabric, the manufacturing process the team used to develop the fabric is also full of potential.

“The strategies used for endowing our materials with breathability, washability, and fabric compatibility could be translated to several other types of wearable systems, such as washable organic electronics, stretchable e-textiles, and energy-harvesting triboelectric materials.”

LET FRIENDS DIVE DEEP By Sharing This on Social Media…