A new ‘smart’ form of packaging could eradicate food poisoning, according to a new study.

Scientists say it kills harmful bugs—such as E.coli, Salmonella, and listeria—keeping meat, fish, fruit, and veg fresh for longer.

The waterproof wrapping may also help save the planet by reducing waste, according to the research team. It looks just like plastic—but is biodegradable.

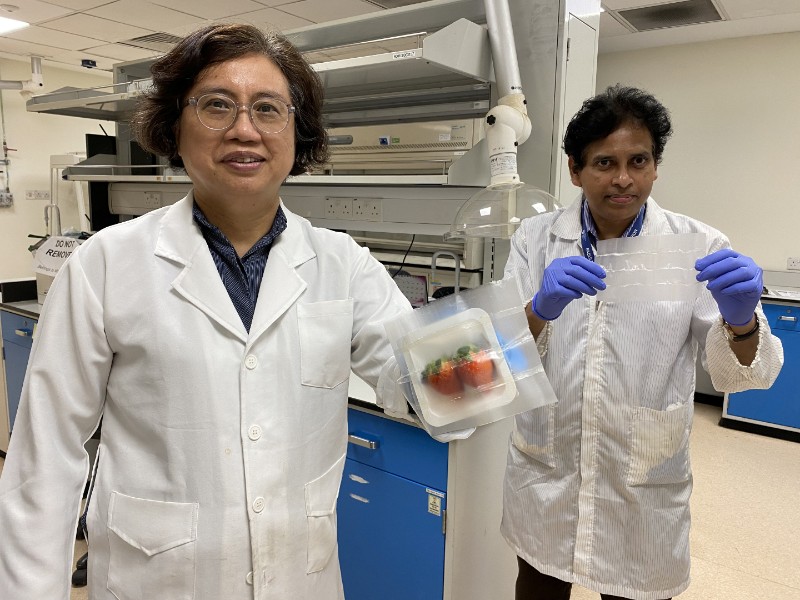

Project co-leader Professor Mary Chan, of Nanyang Technological University, Singapore, said, “This invention would serve as a better option in the food industry.

“It has demonstrated superior antimicrobial qualities in combating a myriad of food-related bacteria and fungi that could be harmful to humans.

“The smart release of antimicrobials only occurs when bacteria or high humidity is present.

“It provides protection when needed—thus minimizing the use of chemicals and preserving the natural composition of foods packaged.”

The transparent material is made from starch, a type of corn protein called zein, and other naturally derived biopolymers.

It’s also infused with a cocktail of anti-microbial compounds found in plants.

CHECK OUT: New Hydrogel Tablet That Can Purify a Liter of River Water in an Hour

They include oil from thyme, a common herb used in cooking, and citric acid found in oranges and grapefruits.

In experiments tiny amounts were only released when exposed to humidity or enzymes from bacteria and fungi that contaminate food.

This ensures the packaging can endure several exposures—and last for months.

The chemicals destroy any bacteria that grow on the surface—as well as on the product itself.

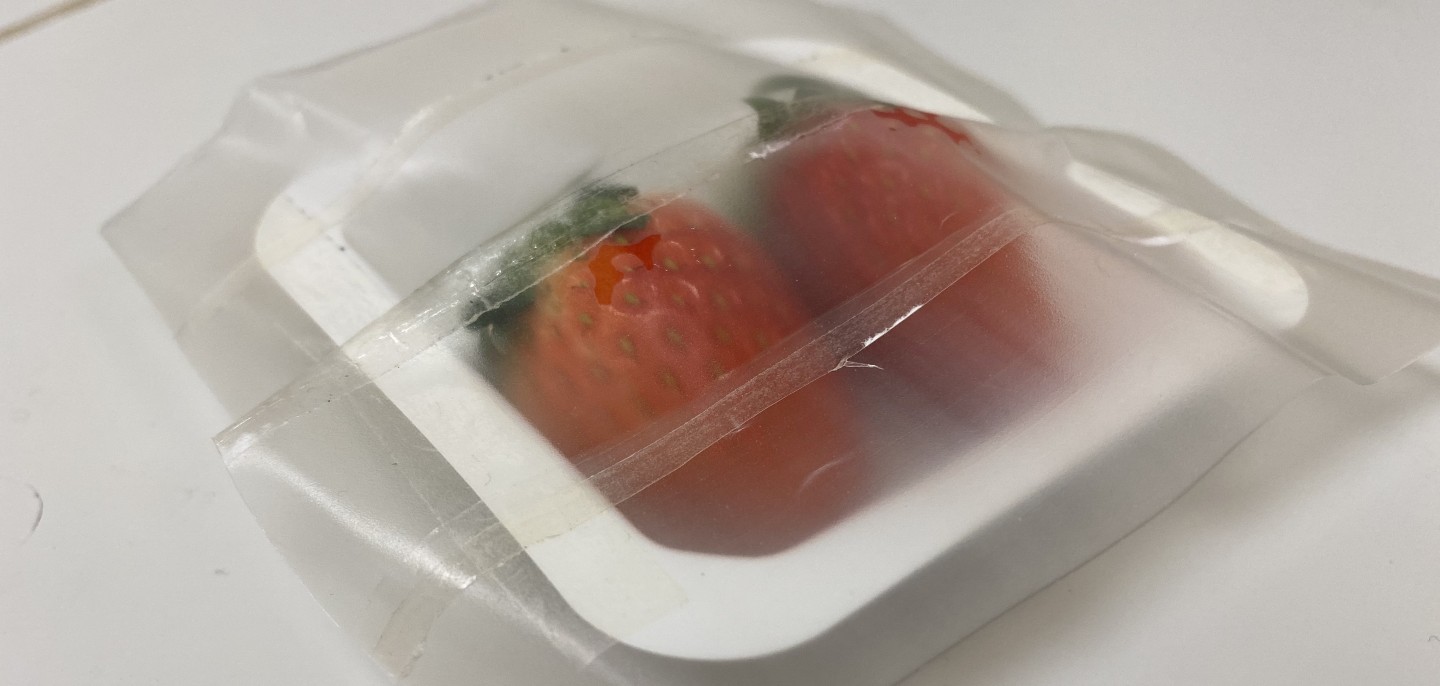

Strawberries stayed fresh for seven days before developing mould—three days more than counterparts in mainstream plastic boxes.

Co-project leader Prof Philip Demokritou, of Harvard TH Chan School of Public Health, Boston, said, “Food safety and waste have become a major societal challenge of our times with immense public health and economic impact which compromises food security.

“One of the most efficient ways to enhance food safety and reduce spoilage and waste is to develop efficient biodegradable non-toxic food packaging materials.

“In this study, we used nature-derived compounds including biopolymers, non-toxic solvents and nature-inspired antimicrobials and develop scalable systems to synthesize smart antimicrobial materials.

“They can be used not only to enhance food safety and quality but also to eliminate the harm to the environment and health and reduce the use of non-biodegradable plastics at global level and promote sustainable agri-food systems.”

The packaging industry is the larges consumer of synthetic plastics derived from fossil fuels.

It accounts for the bulk of plastic waste that is polluting the environment.

Peter Barber, CEO of ComCrop, a Singapore company that pioneered urban rooftop farming, said, “The NTU-Harvard Chan School food packaging material would serve as a sustainable solution for companies like us who want to cut down on the usage of plastic and embrace greener alternatives.

RELATED: UK’s Largest Vertical Farm that Uses Only Sunlight Begins First Harvest

“As ComCrop looks to ramp up product to boost Singapore’s food production capabilities, the volume of packaging we need will increase in sync, and switching to a material such as this would help us have double the impact.

“The wrapping’s antimicrobial properties, which could potentially extend the shelf life of our vegetables, would serve us well.

“The packaging material holds promise to the industry, and we look forward to learning more about the wrapping and possibly adopting it for our usage someday.”

Prof Chan said it has enormous implications—serving as an environmentally friendly alternative.

The aim is to replace conventional plastic packaging with the new material that will also double the shelf life of produce.

Prof Chan said, “Vegetables are a source of wastage because even if they are refrigerated, they will continue to respire, leading to spoilage after a week or two.

“With the anti-microbial packaging, there is a chance to extend their shelf life – and also make the vegetables and fruits look fresh with time.”

The team hope to scale up the technology with an industrial partner—with the aim of commercialization within a few years.

The findings were published in the journal ACS Applied Materials & Interfaces.

SHARE…